HVAC for Passenger Rail Cars

We have repeat orders from many of our satisfied client's all of which we are appreciative of. This particular rack is unique because it combines our steel rack design skills and our knowledge on corrosion prevention. The product being protected is the heating and cooling system for passenger train cars. The unit is mounted to the roof of the rail car. The outside of the HVAC is built to be exposed to the elements.

The underside of the HVAC is not – it houses controls, valves, sensors, circuit boards along with intake and outflow connective duct work. The HVAC is made of many different types of metals that would be damaged if not properly protected with a multi-metal VCI material.

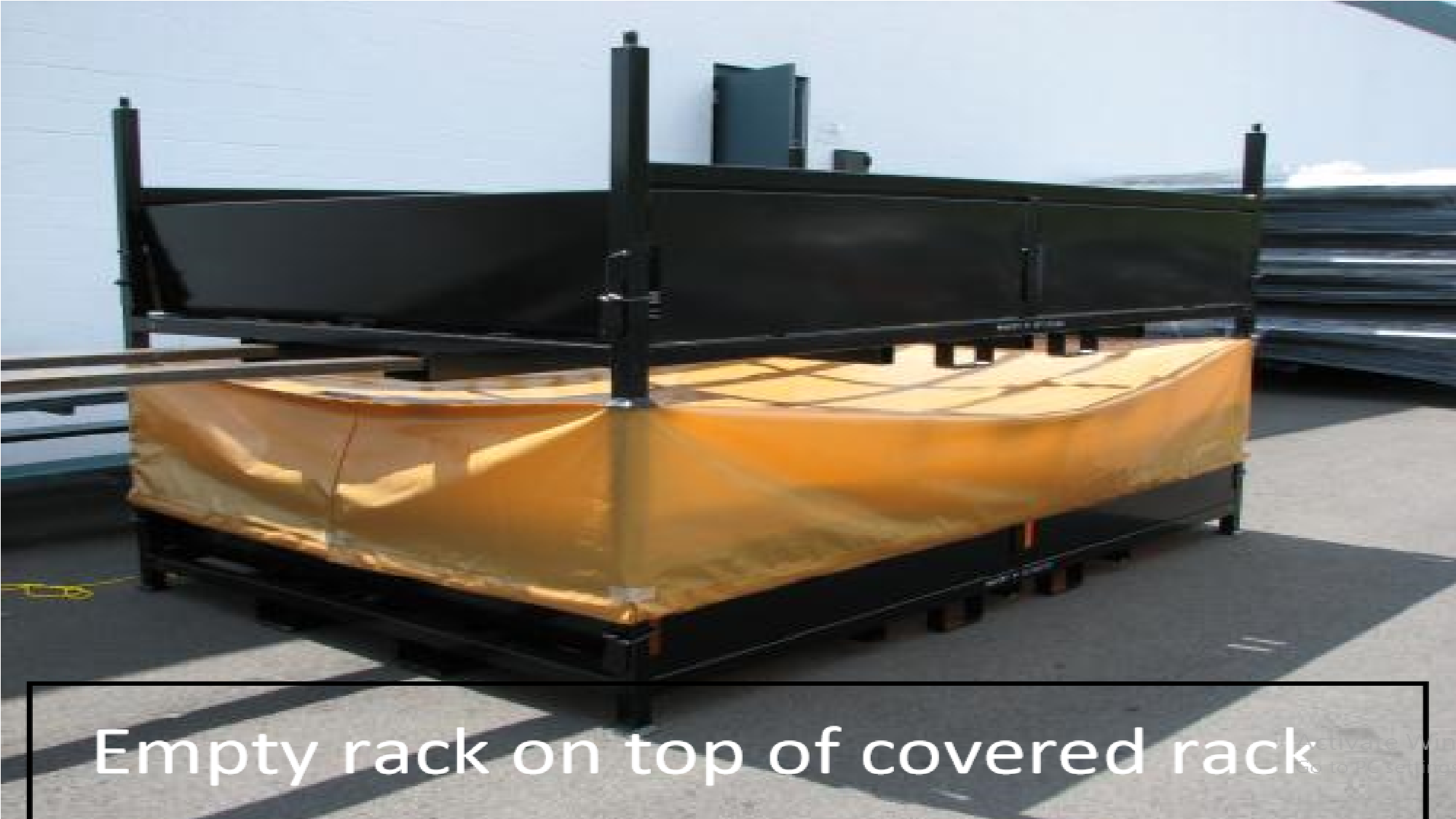

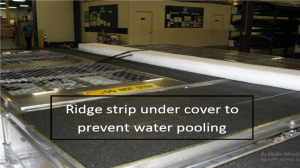

To make this a more interesting challenge the clients – customer will store the rack with the HVAC outside in the train building yard because of space constraints. The rack and HVAC could sit outside for upwards of 12 months in the Northeast weather. With summer heat and winter freezing cycles, each season will create condensation on and in the HVAC. Condensation will create rust and rust is unacceptable. The material and design is proven successful since 2008. Water may collect and it will exit via the net underbelly of the package.

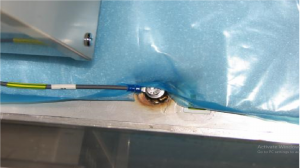

The tan film is Cortec MilCorr developed for extreme weather, loaded with Cortec VpCI (vapor phase corrosion inhibitors). VpCI molecules are attracted to all of the different metal surfaces. These molecules attach to the metal and repel condensation and oxygen from the surfaces. We used a combination of VpCI materials to create an envelope of protection that is safe for everyone. When the customer is ready to install the HVAC they simply remove the packaging cover, lift the HVAC from the rack. We use foam blocks with VpCI film covers to block the numerous openings on the HVAC. The systems we designed are fast and easy to install. Everything is easily recyclable.

Is your company manufacturing items that are prone to rust, but are stored for long or short periods of time? Warranty claims from items delivered with rust damage will occur if products are not properly protected. We have dry packaging solutions that are laboratory tested, field proven to be effective and priced to be cost effective. Our choice of materials and the design are based on the individual applications needs and the expectations of storage, time, conditions and handling.

About The Author