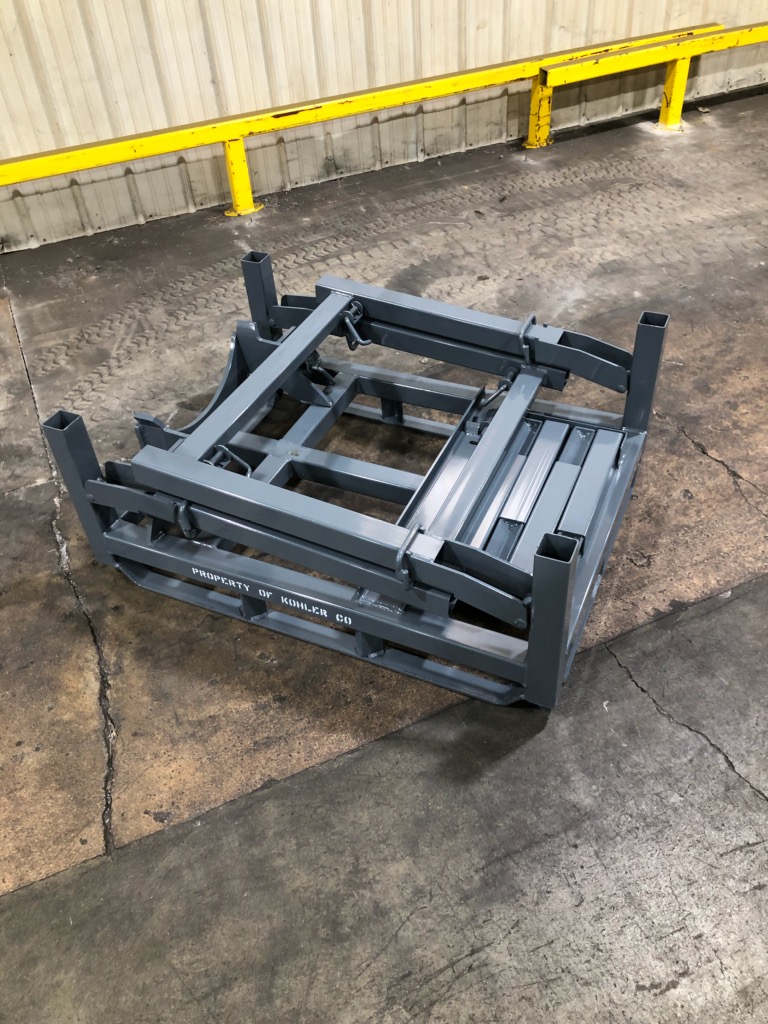

SPS has designed this 3-position steel modular engine rack stand to move engines for a major manufacturer in the recreational vehicle market. This unique design can hold 3 engines at 500 lbs each, and the rack weighs only 225 lbs and allows for 4 way fork truck entry. This engine rack stand utilizes a modular mounting system that allows for removable engine mount strips and customization for different engine models.

Features & Benefits of Motor Racks

Components of Steel Modular Engine Racks

The frame structure is a critical component of metal rack stands. It serves as the backbone, providing stability and support for the entire system. The choice of material is essential, with high-quality steel such as stainless steel or carbon steel being common options. This robust material ensures the strength and durability needed for engine storage. The design of the frame often features a modular construction, allowing for easy customization and expansion. This versatility is crucial for accommodating engines of varying sizes and weights.

Shelves and platforms within steel engine storage stands are essential for efficient organization and access. The choice of material for these surfaces, typically robust steel, is vital to ensure they can support heavy engine loads reliably. Customizability is a key feature, allowing users to adjust the shelf heights to accommodate engines of different sizes and shapes. Some shelves and platforms may incorporate ventilation features, such as perforations or ventilation holes, to facilitate airflow, which is particularly important for engines to prevent overheating.

Mounting brackets are crucial components for securing engines and related equipment within metal rack stands. These brackets prevent items from shifting during transportation or storage, ensuring the safety of both the equipment and personnel. The design of these brackets can vary, with options like L-shaped brackets, clamps, or custom fixtures, depending on the specific needs of the rack or stand. The primary purpose of mounting brackets is to provide security, ensuring that engines are firmly attached to the rack or stand, minimizing the risk of accidents or damage.

Casters and leveling feet play a crucial role in determining the mobility and stability of engine storage stands. The choice between these options depends on the specific application.

Casters: Casters are wheels or wheel assemblies attached to the base of the rack or stand, allowing for easy movement and relocation. Casters are particularly useful when mobility is a priority. Lockable casters provide stability when needed, ensuring the rack or stand remains stationary during use.

Leveling Feet: Leveling feet are adjustable supports attached to the rack or stand’s base. These are used to ensure stability, especially when the surface beneath the rack or stand is uneven. By adjusting the height of each corner, leveling feet ensure that the rack or stand remains steady, even on irregular surfaces.

Technical Specifications and Standards of Engine Rack Stand

Engine rack stand are designed to safely and securely store and transport heavy engine components. The technical specifications of engine racks include load capacity and weight limits, which ensure that the racks can effectively handle the weight and size of the engines. Some key points to consider regarding load capacity and weight limits are:

Engine storage racks are subject to industry regulations and standards to ensure safe handling, transportation and storage of engines. Compliance with these regulations is essential to maintain workplace safety and meet industry requirements. Some aspects of compliance to consider are:

SPS Ideal Solutions provides the engine rack stand at competitive prices. If you would like to know more about our metal pallet offerings, please send us an email at info@spsidealsolutions.com.